Recently, multiple rounds of cold waves have hit frequently from north to south. Many parts of the world have experienced bungee-style cooling, and some areas have even received their first round of snowfall. In this low temperature weather, in addition to everyone's daily travel, the production of packaging and printing companies has also been affected to a certain extent.

So, facing such a harsh climate, what details should packaging printers pay attention to?

Prevents web offset inks from thickening in cold weather

For ink, if the room temperature and the liquid temperature of ink have changed changes, the state of ink flow will change, and the color will change accordingly. At the same time, the low temperature weather will have a significant impact on the ink transfer rate of the high light area. Therefore, when printing high-grade products, the temperature and humidity of the printing workshop should be controlled in any case. In addition, the use of ink in winter should be preheating in advance, in order to reduce the temperature change of the ink itself.

Note that the ink is too thick and the viscosity is large, but it is best not to use thinner or ink to adjust its viscosity. Because when the user needs to mix ink, ink factory produced raw ink can accommodate a total number of additives is limited, beyond the limit, even if can be used, also weakened the basic performance of the ink, affect the printing quality printing technology.

Pay attention to the use of anti-freeze UV varnish

UV varnish is also a material that is easily affected by low temperatures. Therefore, many suppliers specialize in producing two different formulas, winter type and summer type. The winter formula has a lower solid content than the summer formula, which can make the leveling performance of the varnish better when the temperature is lower.

Note that if you use a winter formula in summer, it will easily cause the oil to be incompletely cured and may lead to back-sticking. On the contrary, if you use a summer formula in winter, it will cause poor leveling performance of the UV oil, causing blistering and orange peel problems.

The effect of cold weather on paper

In printing production, paper is one of the consumables with high requirements for environmental temperature and humidity. Paper is a porous material, and its basic structure is composed of plant fibers and accessories, with strong hydrophilic properties. If the environmental temperature and humidity are not well controlled, it will lead to paper deformation and affect normal printing. Therefore, maintaining the appropriate environmental temperature and humidity is the key to improve the quality of paper printing products and improve the production efficiency.

Ordinary paper for the environmental temperature requirements are not so obvious, but when the environmental temperature is lower than 10℃, ordinary paper will become very "brittle", the adhesion of the ink layer in its surface will decline, easy to cause deinking phenomenon.

Gold and silver card paper is usually made of coated paper, white board paper, white card paper as the base material, and then composite PET film or aluminum foil and other materials produced. Gold and silver card class paper some higher requirements for environmental temperature, this is because the metal and plastic material is very sensitive to temperature changes, when the environmental temperature is lower than 10℃, will greatly affect the gold and silver card class paper suitability, when gold and silver card class paper storage environment temperature around 0℃, from the printing workshop, the surface will be a lot of water vapor, affect the normal printing, can even lead to waste. If the above problems are encountered, and the delivery time is tight, the staff can first open the UV lamp tube to let the paper run empty again, so that the temperature and the ambient temperature balance before formal printing.

In addition, low temperature drying, low relative humidity, paper and air moisture exchange, the paper becomes dry, become warped, contraction, will cause poor overprinting.

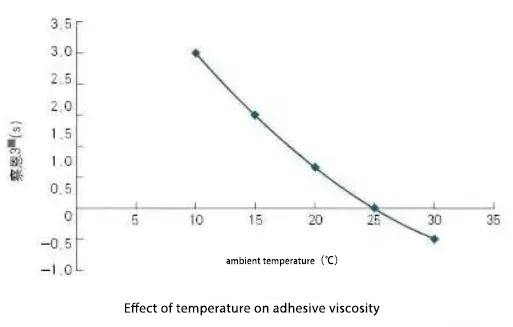

Effect of low temperature on the glue adhesive

Adhesive is an important chemical preparation in industrial production nowadays. The performance of adhesive directly affects the quality of industrial products. An important technical index in the production of adhesives is the control of temperature. Most of the raw materials of adhesives are organic polymers, which have a high degree of temperature dependence, which means that their mechanical properties and viscoelasticity are affected with the change of temperature. It should be pointed out that low temperature is the main culprit of the glue false adhesion.

When the temperature drops, the hardness of the adhesive becomes hard, and the stress at the adhesive is changed. In the opposite low temperature state, the polymer chain movement in the adhesive is limited, reducing the scalability of the adhesive.

Post time: Dec-21-2023