Die-cutting and creasing originated from letterpress printing, which uses molds to cut materials into a series of different shapes, designs and patterns, which helps to tell the brand story and enhance the user consumption experience.

Definition: Die-cutting and creasing are also called pressing and forming, buckling knife, etc. When the packaging and printing paper box needs to be cut into a certain shape, it can be completed through the die-cutting and creasing process. Die-cutting is a process of rolling and cutting paper into a certain shape on a die-cutting machine by arranging steel blades into a die (or carving a die with a steel plate), a frame, etc. The hollow part of the main display surface in the middle is obtained by the die-cutting process, which becomes a personalized decoration in the entire packaging. Crimping is to use steel wire to press out marks or leave grooves for bending on the paper by embossing. The process of performing die-cutting and creasing processing on the die-cutting machine at the same time is referred to as die pressing.

Features: The die-cutting and creasing process can create special shapes and enhance the packaging expression.

Various forms of die cutting and creasing technology

01 Flat cutting/Edge cutting

The material can be cut directly according to the characteristics of the paper and the design requirements. The ingenious use of flat cutting/edge cutting technology can highlight the artistic sense of packaging.

02 Window opening/hollowing

Cut inside the paper to create layers on the basis of a single sheet of paper. The use of window opening/hollowing helps to create a three-dimensional sense of packaging, which is the most commonly used die-cutting process in packaging.

03 Line marks

Leave dotted cuts in the designated area to facilitate tearing when needed. Line marks are of two types: dots and dots. The paper seems to be broken but not broken, and seems to be connected but not connected. It is easy to tear or cut along the line. The density is orderly and the practicality and form are excellent.

04 Creases

A crease is to set a folding line. There are single-line marks, double-line marks and positive and negative creases. Thinner paper uses single-line marks, and thicker paper uses double-line marks. Multiple folds and positive and negative creases are often used for pulling pages.

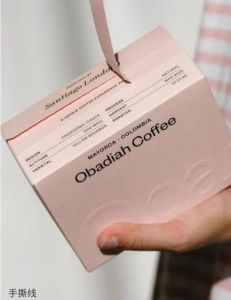

05 Hand-tear lines

Leaving a series of small cuts for easy tearing, it is often used for packaging sealing. It is an interesting way to open, easy to tear along the line, with orderly spacing, practicality and form.

The die-cutting and creasing process changes the single straight line or plane form of printed products, allowing various printed packages to be presented in three-dimensional and curved forms, creating a variety of shapes and shapes that are more beautiful and exquisite, full of creativity and wisdom, and help improve the quality of packaging.

Post time: Apr-24-2025