Packaging printing is an important way to enhance the added value and competitiveness of commodities. It is the best way to help the sellers open up their markets. Designers who can understand the printing process knowledge,can make the designed packaging works more functional and beautiful.

Traditional printing methods:

(1) Letterpress printing

(2) Gravure printing

(3) Offset printing

(4) Screen printing

Among them, let’s talk about the gravure printing.

The graphic part of the printing plate is lower than the non-graphic part, which forms to be a groove shape. The ink is only covered in the groove and there is no ink on the surface of the printing plate.Then we make the paper overed on the upper part of the printing plate, let the printing plate and the paper are pressurized so that the ink is transferred from the concave part of the printing plate to the paper.

The printed products with gravure printing have thick ink layer and bright colors, at the same time, the printing plate has the advantages of high printing durability, stable printing quality and fast printing speed, so it has been widely used in practice.

The common printing process of packaging

Four-color printing

1. The four colors printing are: Cyan (C), Magenta (M), Yellow (Y) and Black (K) these four inks.All colors can be formed by mixing these four inks and finally realize color graphics.

2. This is the most common printing and its effect is different on different substrates.

Special color printing

1. Special color printing refers to use a special ink for printing the color, which is brighter than the mixture of four colors. Normally,we used the special gold color and the special silver.

2. There are many special colors. You can refer to the pantone color card. But the special color can not achieve gradient printing,so it needs to add four-color printing to achieve it.

The over light glue process

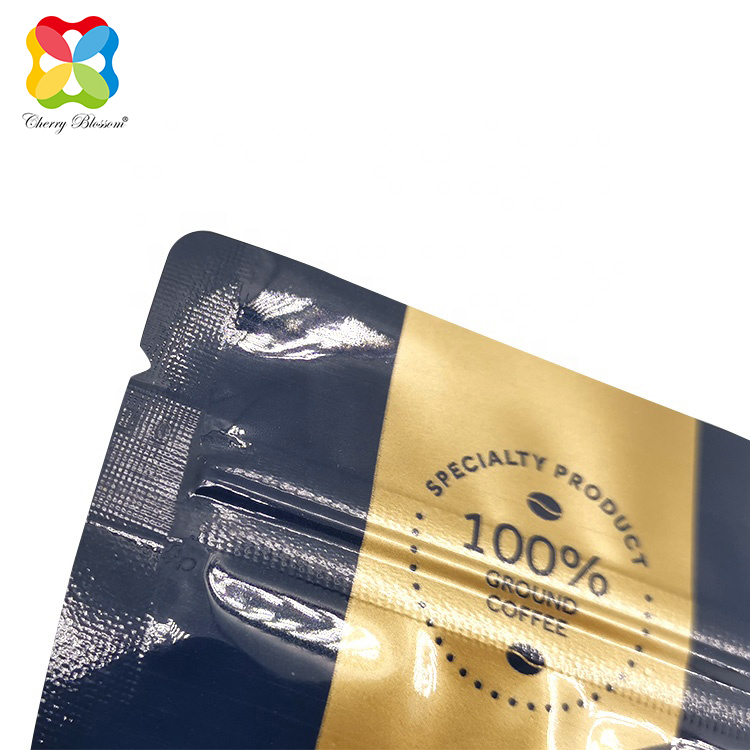

1. After printing, the transparent plastic film is applied to the surface of the print matter by hot pressing to protect and increase the luster. The surface is bright, see the following picture

2. The most basic process of paper box is surface treatment. Similarly, there is a over light oil, but the light glue process can enhance the hardness and tensile properties of the paper.

Matt film

1. After printing, the transparent plastic film is applied to the surface of the print matter through hot pressing to protect and increase the luster. The surface is matte, see the figure below.

2. The most basic process of surface treatment of the carton is similar to the over-light glue, but the over-glue can enhance the hardness and tensile resistance of the paper.

More printing information,please contact us.

Post time: Aug-01-2023